What is MAKIN’ 3D?

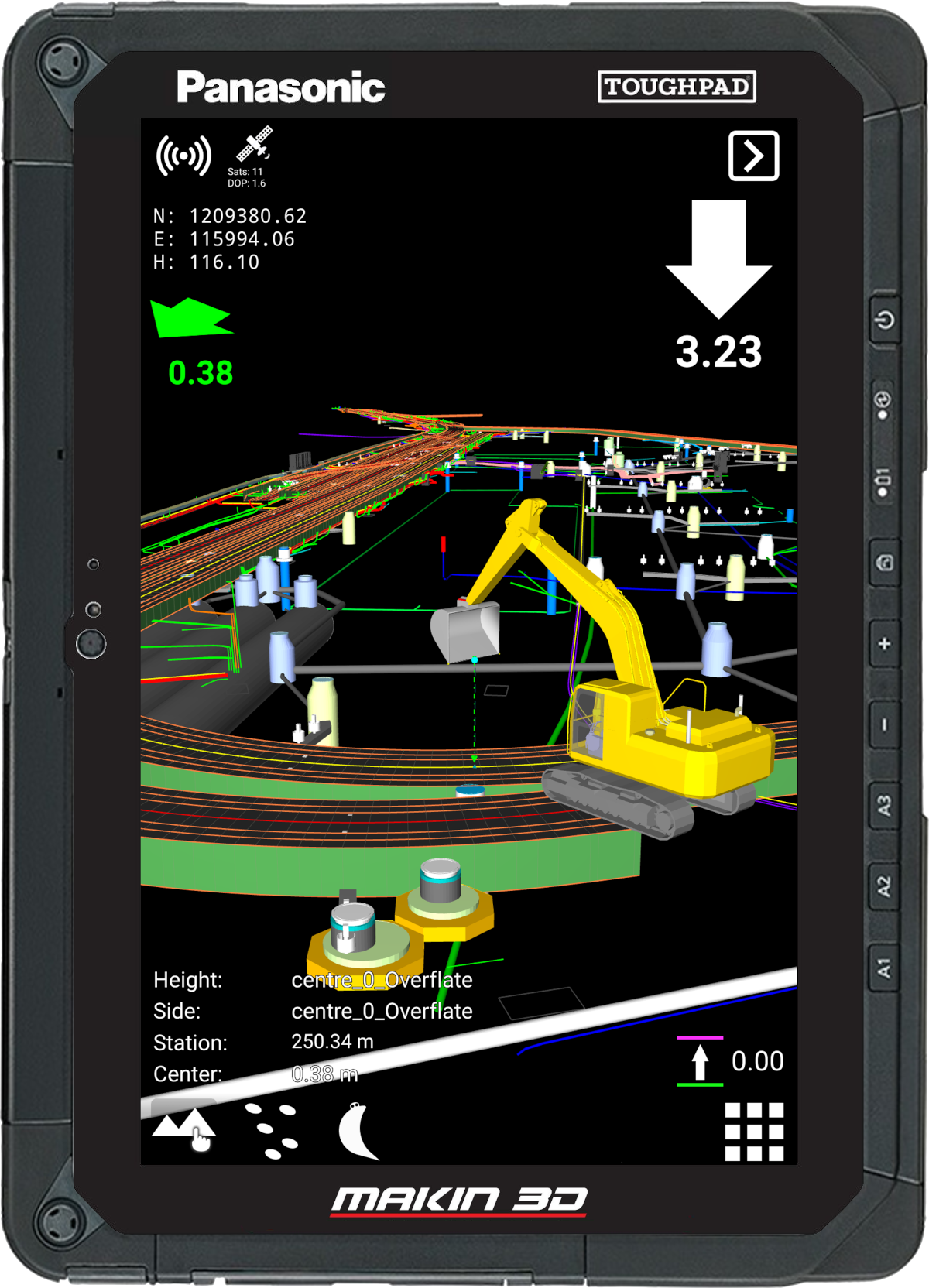

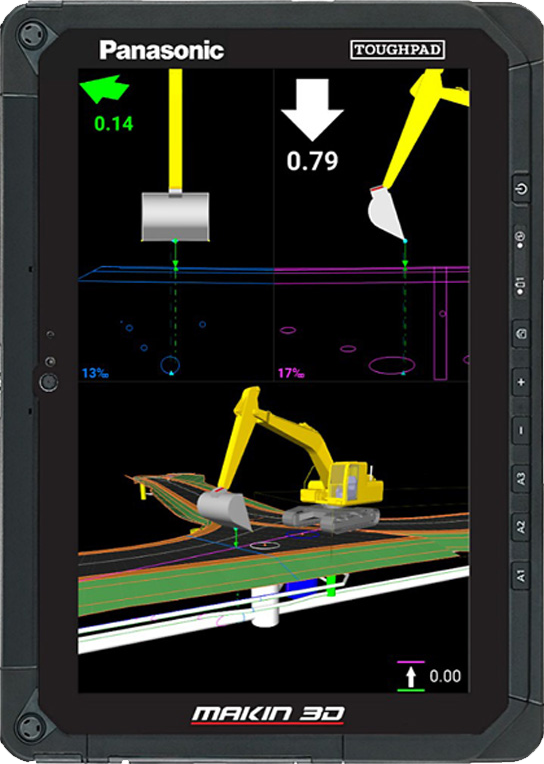

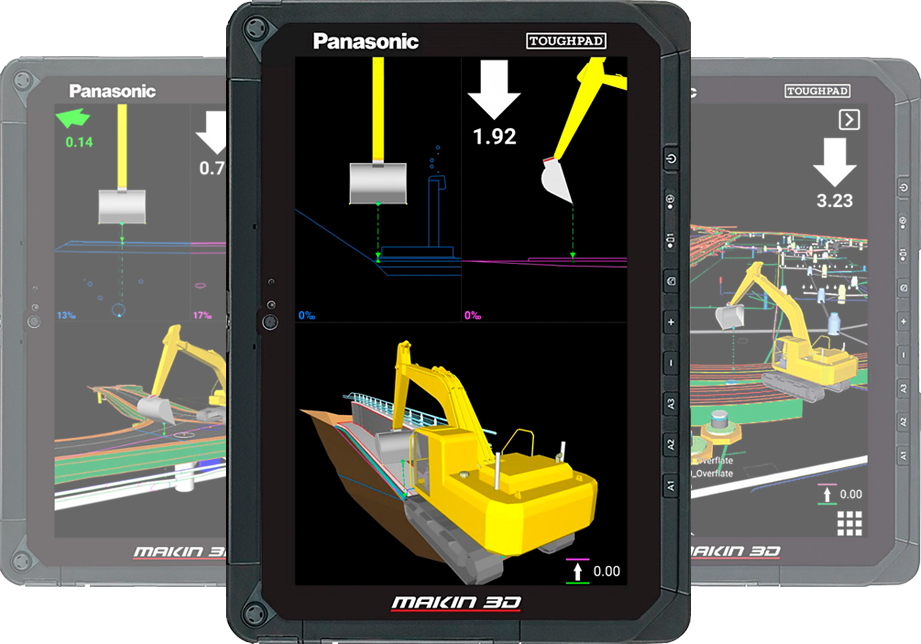

Machine control is a system that shows the machinist in real time the position of the bucket via our smart sensors that are placed on the bucket/stick/boom/body together with a GNSS (Global Navigation Satellite System) box and antennas. It is also possible to work with the Google Maps background.

- The world’s fastest system

- Unique 3D visualization of entire projects

- Live data sharing between machines, surveyors, offices

- As easy to use as your smartphone

Makin’ 3D has a Tablet/Android pad (Panasonic Toughbook) that sits in the cabin, which picks up signals (Can Bus) from Angle sensors on the machine’s moving parts body, boom, stick, scoop, tilt, rotation. Together with GPS/GNSS or total station as position sensor X,Y,Z. When these different angle and position sensors work together in the system, it becomes as easy to navigate the bucket’s position as with your smartphone or GPS in the car.

Welcome to Scandinavia’s most modern machine control! Welcome to the future!

Our systems come with

- 2 year warranty

- 5 years free software update

- Free Cloud Server for remote support file download/drop off

- Completely assembled by us with quality certificate

- Start-up education

Possibility for connection/calibration via the rotor manufacturer’s rotation sensor. Our software is developed in the north for Nordic conditions as it is developed in Denmark and Norway. The system is developed by industry people with many years of experience to people in the industry who broke away from old machine control brands, to create the best digging system on the market. Makin offers ongoing software updates constantly.

Makin offers you the market’s best graphics and the fastest system without “delay”. Our angle sensors have gyro and electronic angle sensor. Our GPS/GNSS receiver included in the system is of Superior Standard. That’s why you should choose Makin, Best performance, Best quality and service support on the market. From people in the industry to people in the industry.

- Full status and map location for all systems

- Centralized control of design data, coordinate systems, embedded data, point codes and more

- Easy remote support for system users

This is your web-based operations center from which you control project data for your fleet – including rental machines. You can easily exchange important information with users and support them remotely. As-built data automatically flows into the project’s data pool and can be easily filtered and exported.

- Android as operating system

- Can be driven towards total station

- Can be run against Makin’ Survey

- Makin’ 3D handles XML, KOF, DXF Direct import and export from Gemini

- Code lists can be applied via Makin’ Cloud and own codes can be entered directly in the field

- Infrakit compatible

- Google maps as background

- The market’s best graphics in the screen

- Colors on 3D models

- Able to load all reference models at the same time. Measured points/lines are collected in Makin’ Cloud

- Live display of other machines/rovers directly in the display

- Unique 3D visualization of models

MAKIN’ 3D

To the most efficient and smartest machinists on the market

Makin’ 3D guides the operator using reference models and GNSS in 3D in Google Maps and via Swepos. Get a positioning for the bucket in real time and read the digital drawings directly via Makin’ Cloud.

With Makin’ 3D, you quickly and easily upload files and layout drawings directly into Makin’ Cloud, so you don’t have to go to the office or load files into your machine control, it happens directly in the cloud. You can also create your own terrain models and drawings where you have height and plan. The ability to see multiple Makin machines in real time at your workplace in your team, as well as the chat function between your systems saves time, fuel and materials and creates efficiency and productivity.

Cloud solution is accessed from all smart devices and is updated directly into your Makin’ 3D toad that you have in the cabin and everyone working on the same project. When you choose Makin’ 3D, 1 year’s free Swepos all built-in radio is included, also a period’s free SIM card/subscription for data traffic Cloud server / remote support / Swepos.

Makin offers you the market’s best graphics and the fastest system without “delay”. Our angle sensors have gyro and electronic angle sensor. Our GPS/GNSS receiver included in the system is of Superior Standard. That’s why you should choose Makin, Best performance, Best quality and service support in the market. From people in the industry to people in the industry.

MAKIN’ 2D (3D Prepared)

For the flexible machinist

Makin’ 2D/3D ready means that your system has the same features as our Makin’ 2D, but the difference is that it is delivered complete with mast and cabling for a quick and easy upgrade to 3D when your needs change. It could be if you are going to a job where the assignment or a larger project that you have taken on requires a 3D license and GNSS connection, don’t worry, we will solve it! With Makin’s smart solutions, you can easily rent 3D equipment for the projects that require it.

The system is also calibrated to GNSS frequency, and can therefore be upgraded to Makin’ 3D quickly and smoothly. If your needs may change, we only turn on the GPS, the GNSS antennas and connect the cables, 3D license and correction data, then you are ready to go.

Makin offers you the market’s best graphics and the fastest system without “delay”. Our angle sensors have gyro and electronic angle sensor. Makin’ you days! That’s why you should choose Makin, Best performance, Best quality and service support in the market. From people in the industry to people in the industry.

MAKIN’ 2D

For the smaller but efficient machinist

With the Makin’ Cloud solution, you have a simple and fast way to remote support.

Makin’ 2D is an easy-to-use and simple measuring system, it registers and shows the position of the bucket with an accuracy of one centimeter in your toad. Makin’ 2D measures depth, height and the slope of the bucket and displays the position of the bucket graphically and numerically on the screen. You never have to stop work to check the height of the bucket, which saves time and increases safety. By using a Makin’s own designed laser receiver in combination with Makin’ 2D and with the bucket as a level reference so you can see that the correct digging depth has been achieved.

Makin’ offers you the market’s best graphics and the fastest system without “delay”. Safe and secure! Works when you do! That’s why you should choose Makin’, Best performance, Best quality and service support in the market. From people in the industry to people in the industry.

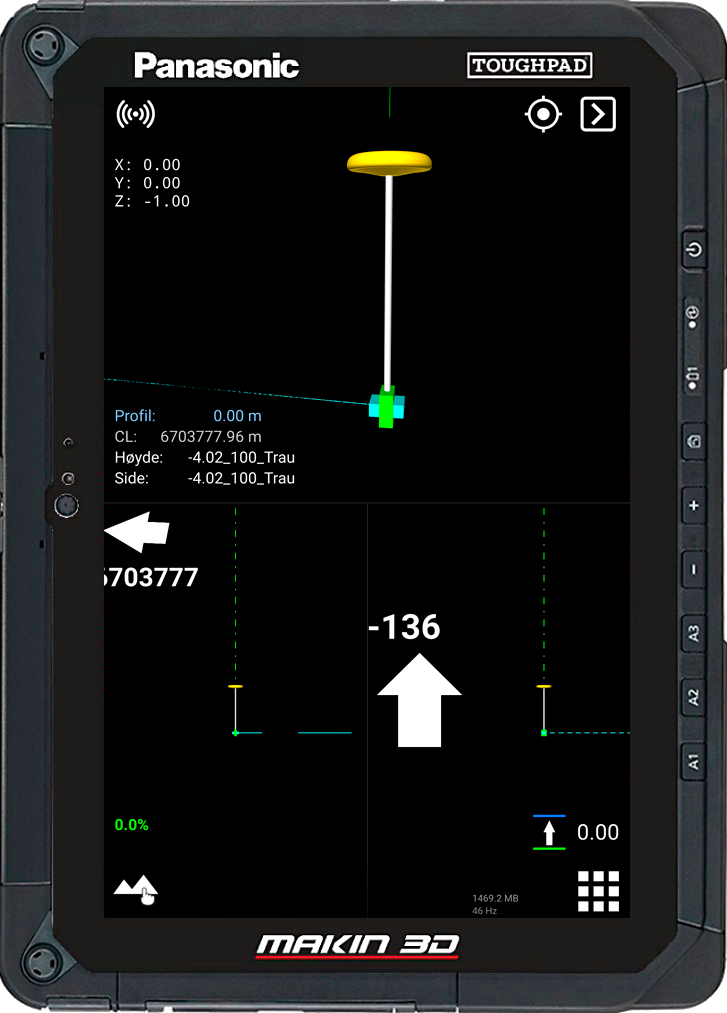

MAKIN’ Survey

Extend your machine control to new heights

Combine your Makin’ 3D with a Makin’ Survey for optimal independence and control. Makin’ Survey is compatible to work together with your Makin’ 3D.

With the GNSS antenna on the carbon rod, the machine operator can take the screen out of the cab and measure in or out what is required to get the job done. With a Makin’ Survey, you can use the same Panasonic toad yourself to measure and create points, lines and files with the Rover and then sit comfortably back in the cab and continue the work.

Read more about the benefits here

MAKIN’ PerFormans

Portable solution for the project manager

An intuitive and portable project control tool for visualizing project data in real time.

Get access to valuable project information and enable smart planning and immediate detection of deviations.

Makin’ PerFormans is workflow integrated with all other Makin’ solutions.

Read more about the benefits here

Contact persons

Don’t know what you need for your business? Relax, we’ll help you.

Johan Andersson